NEED TO CHECK YOUR TIRE, FROM TIME TO TIME.

Effect of a tire on safety of a car is significant but there are no many of drivers to diagnose status of the tire by themselves and prevent possible accident. It is not easy for non-professionals to determine any failure of the tire that is smoothly rolling but you can increase life of the tire and prevent unexpected accident even by checking only wear status, tire inflation pressure and surface failure, etc from time to time. You can diagnose the wear rate by showing indication of the wear limit that appears in a groove of the grounding surface along with direction of a triangle indicated on 6 places around the tread. The wear limit is indicated in the height of 1.6mm from the groove, and if the tire is worn out so as this part is disclosed on the grounding surface (tread), life of the tire is exhausted. It is also possible to diagnose problems of a car by showing wear status of the tire. If irregular wear phenomena that a tread is worn out only in either side occurs or diagonal wear occurs, it is witness that there is failure in alignment. Correct alignment in a professional shop and then replace the tire with a new tire. For irregular wear, if wear level is minimal, you can continue to run the car by replacing the inside / the outside position of the tire but a tire worn out diagonally cannot be used again. Diagonal wear is phenomena when more than 2 complicated problems exist in the car frame and alignment, and the tire loses its performance in respect of noise, vibration and grip power, etc.

SURFACE ABNORMALITY CHECK

A tire informs abnormal signal firstly to the surface before accident occurs. If abnormal signal appears on the surface, it means that the tire has critical damage non-repairable. In the following case, unconditionally replace a tire with a new one and it is good not to reach to such status through a regular checking if possible.

Case 1. Separation

Separation means phenomena that adherence of a tire composing multi-layers of rubber falls down and the multi-layers of rubber are separated each other. Such phenomena frequently occurs in a freight truck of more than light truck level and when a truck runs at excessive speed with tire inflation pressure deficient or when much load is suspended due to overload, etc. If such phenomena would occur in a passenger car, it is resulted from that a tire is very aged and thus inner steel cords are eroded and adhesive power falls down. Initial symptom of separation is case that a tire is worn out as a peel is partially gotten stripped off while the tread surface is lengthened or inner steel cords are extruded as a seam.

Case 2. Bead Damage

Bead is inner diameter part of a tire and is not hided inside of the wheel when it is mounted in a car. Damage of this part occurs during mounting or demounting work almost. Damage occurs when cut damage happens at a tire bead during assembly since a mounting/demounting device is old and its end is sharpened by wear or when a poor worker causes to damage a tire. Since damage of the tire bead may result in accident within two or three days, consult with a reliable professional shop when checking a tire in a usual time and effort of carefully checking the side surface even during work.

Inflation Pressure 32psi

Case 3.Cord Break-Up

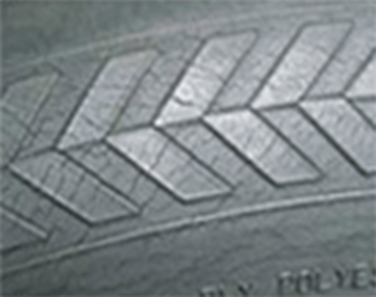

Cord Break-Up is phenomena when polyester cords contained in the side of a tire are cut. In appearance, cord surface is extruded as a bump arises by which a strong pressure acts to the part where polyester cords are cut. If a shape of tire looks slightly distorted or an extruding part arises in the side surface of tire, it means a red signal. Extra care must be taken since cutting of a tire cord is easily done by shock on account of it if not reducing speed when a car passes an obstacle, a curbstone or a mud puddle on the road surface.

TIRE LNFLATION PRESSURE CHECK

Even though recommended values of a proper tire inflation pressure differ every tire product or every type of car, 28 through 32 psi must be standard for a general passenger car. It is difficult to visually diagnose status of the tire inflation pressure but refill of air should be rapidly done since the tire inflation pressure is reduced below 15psi if a tire looks subsided. There is also method to determine excessive or deficient tire inflation pressure by showing wear status of a tire and only both sides of tread are worn out if the tire inflation pressure is deficient and only central part is worn out if it is excessive.

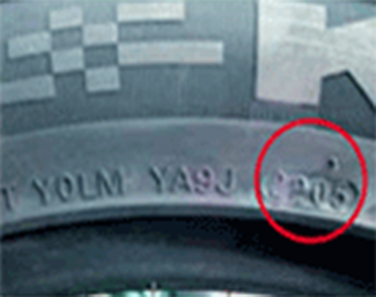

How to diagnose tire aging

Aging is rapidly done regardless of use period and wear status, etc if 3 years have eclipsed from the manufacturing date. Therefore, it is essential to check the manufacturing date when diagnosing aging of a tire. Manufacturing number is indicated on the sidewall in the form of 'DOT xxxxxxxx0205' and Arabia number in the rear side is manufacturing date. 3 digits are used to 1999 year and 4 digits are used from 2000 year. 0205 means product produced on the 2nd week in 2005 and 459 means product produced on the 45th week in 1999. Another method to diagnose aging is to view surface split phenomena called as 'Side crack'. A honey layer arises like human skin and is cracked if endurance power of a tire reduces and limit life is exceeded. Crack arises more frequently on the salty seashore or the downtown area with much ozone or when stress is severe such as deficient tire inflation pressure or overload.

korea

korea

china

china

japan

japan

vietnam

vietnam

australia

australia

thailand

thailand

germany

germany

uk

uk

spain

spain

austria

austria

russia

russia

poland

poland

france

france

italy

italy

NE/BAL(EN)

NE/BAL(EN)

TÜRKIYE

TÜRKIYE

usa

usa

canada(EN)

canada(EN)

brazil

brazil

egypt

egypt