A tire subject to endless shock and vibration from the road surface during traveling and harassed by severe high temperature is always disclosed to danger of puncture. Safety technology of a tire focuses to reduce possibility of this puncture and minimize result of this puncture.Representative technology is a run flat tire. A run flat tire has two structures based on SR and SRM method and a TPMS system, which is usually a device to detect tire inflation pressure is also applied to together..

RUN FLAT TIRE

Appearance of a run flat tire after puncture

Appearance of a general tire after puncture

A run flat tire means product that a car can run 80 through 200km at speed of 80km per hour even after puncture with preparation of enforcing device inside of a tire. A run flat tire firstly released at American markets in 1990 year did not enjoy a large positive response as passenger's comfort fell down but now emerges as the top alternative market since UHP tire as problems are completed by continuing technology development.Because of advantage in safety that eradicated danger of accident caused by tire puncture, there are many cars equipped with a run flat tire as basic option and this tire appeals to specially women drivers facing difficulty in replacement of spare tire.

SSR

Technology to Support weight in case of puncture by enforcing inner wall of tire

Principle of a run flat tire is to make a car to continuously run constant distance by preventing appearance of a tire from being subsided due to leakage of tire inflation pressure when a tire puncture occurs.Depending on method to make it possible, the run flat tire can be classified into two types. Firstly, it is a SSR(Self Support Reinforce) type to enforce the sidewall.This is technology to maintain the appearance of a tire some degree so that it is not entirely subsided, even after the tire inflation pressure is exhausted when raising rubber strength of the sidewall (side surface) that is basic skeleton of a tire. In the early development of a run flat tire, this method was mainly used.

A run flat tire means product that a car can run 80 through 200km at speed of 80km per hour even after puncture with preparation of enforcing device inside of a tire. A run flat tire firstly released at American markets in 1990 year did not enjoy a large positive response as passenger's comfort fell down but now emerges as the top alternative market since UHP tire as problems are completed by continuing technology development.Because of advantage in safety that eradicated danger of accident caused by tire puncture, there are many cars equipped with a run flat tire as basic option and this tire appeals to specially women drivers facing difficulty in replacement of spare tire.

SR

SR (Support Ring) type

Technology to Support load in occurrence of puncture by mounting a ring on the inside of a tire. Another composition method of a run flat tire is a SR (Support Ring) type. This method is based on principle to make that a tire can travel with Support of this ring even though tire inflation pressure is exhausted by inserting a ring over the wheel, namely inside of a tire. Examining the inside structure of a ring type of tire, hard ring part is manufactured of a round band and firmly adhered to the wheel surface.Depending on tire maker, this ring parts, whose new materials is continuously developed and with which a rubber or steel material is used, prevents a rubber layer being entirely subsided due to high rigidity.

Most of worldwide tire makers hold a soft ring type of and sidewall enforcement type of run flat technology, and each of two types has advantage or disadvantage and so either type is not standard type. A ring type of run flat tire has advantage capable of maintaining same passenger comfort as general tire but it is difficult to handle.That is why A/S is inconvenient since a tire service center with mounting/demounting device is rare all over the world. This type of ring is not well applied to low series of tire because there is basic area where a ring takes charge inside of a tire but is often used for a large car with large series. A Support ring type is classified into a separate type to use exis used for a ting wheel by inserting a separate ring between tire and wheel and a single type to required dedicated wheel. (Insert a Support ring between tire and wheel.)

TPMS

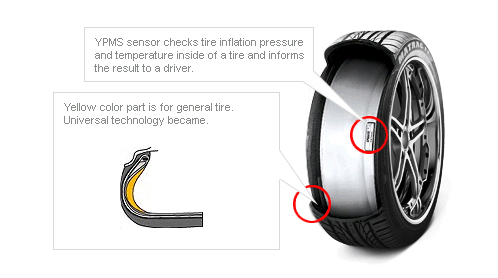

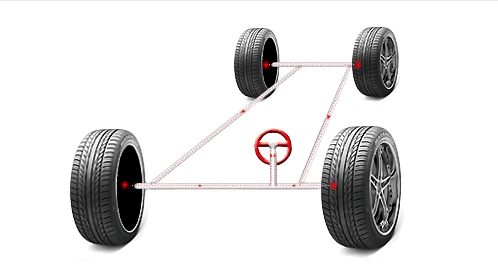

The TPMS is a tire inflation pressure monitoring system to inform tire inflation pressure and temperature status to a driver using a sensor adhered to the inside of a tire. By informing tire status to a driver from time to time, this system prevents accident of car overturn, etc due to puncture. The TPMS system consists of 4 wireless transmission sensors, antenna to receive transmission contents and display (LCD monitor) etc and a driver obtains all types of information about tire through a LCD monitor in a car.This system is based on method to assemble 4 wireless transmission sensors with the inside of a tire valve. It is also very easy to mount or remove the system. In America, mounting of the TPMS will be regulatory from November 2005 by stages and be applied to all cars in November 2006. If so, the market size will be amounted to 100 million dollar.

korea

korea

china

china

japan

japan

vietnam

vietnam

australia

australia

thailand

thailand

germany

germany

uk

uk

spain

spain

austria

austria

russia

russia

poland

poland

france

france

italy

italy

NE/BAL(EN)

NE/BAL(EN)

TÜRKIYE

TÜRKIYE

usa

usa

canada(EN)

canada(EN)

brazil

brazil

egypt

egypt